One, the bearing use matters needing attention One, the bearing use matters needing attention

Rolling bearing is a precision components, its use must be carefully. Regardless of how high performance bearing, if used improperly will not get the expected high performance. The bearing use matters needing attention are as follows:

( 1 ) to maintain the bearing and its surrounding clean, even the eyes can not see the small dust, will also give the bearing has a bad influence on. So, to keep the surrounding clean, so that dust from low income inner bearing.

( 2) circumspect use, in use for bearing a strong impact, will have a scar and indentation into the cause of the accident. In severe cases, can crack, fracture, so attention must be paid to.

( 3) must use the discovery when operation tool, in order to avoid the existing tools instead of.

( 4) attention to bearing corrosion, operating bearing sweat from the hands will become rusty reason. Pay attention to clean hands operation, the best to put on gloves.

( 5) the user should be familiar with bearing.

(6 ) developed bearings using standard operation;

Bearing news

Bearing and its cleaning

Installation parts of the ruler and the processing quality inspection

Installation work

After the installation of the examination

Disassembly operations

Maintenance ( check )

Lubricants are added |

Two, bearing news

Bearing at the factory are coated with the right amount of rust preventing oil and packaging barrel packaging, as long as the visit department of packaging is damaged, the bearing quality will be ensured. But to be stored for a long time, the humidity is lower than 65%, temperature 20”ęcondition, stored in the above ground 30cm frame is appropriate. In addition, the custody of the places should avoid direct sunlight or with cold wall contact.

Three, bearing mounted front matters needing attention

1) bearing preparation

Because the bearing after antirust processing and packaging, so do not come before installation not to open the packing.

In addition, the bearing coated antirust oil has good lubricating performance, for general purpose bearing or filling grease for bearings, it is not necessary to clean used directly, but to instrument bearing for high speed rotating bearing, application of clean cleaning oil antirust oil wash, the bearing is easy to rust, not a long time place.

2) shaft and the casing inspection

The cleaning shaft and the housing, convinced that no scar or no machining burrs left. Shell absolutely not grinding ( Sic, AI204 ), sand, chips. The second test of shaft and shell size, shape and machining quality and drawing with. |

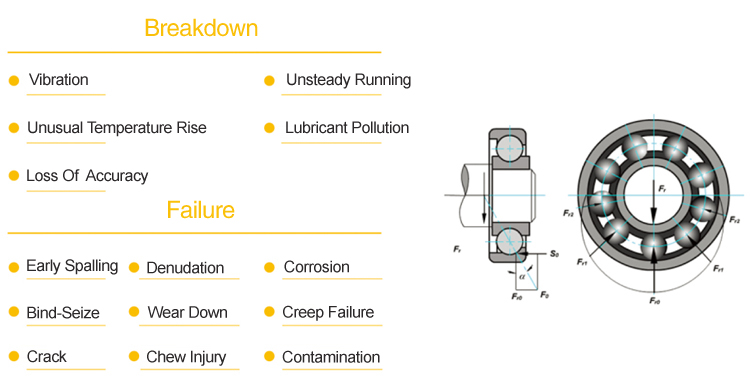

Failure and failure reasons

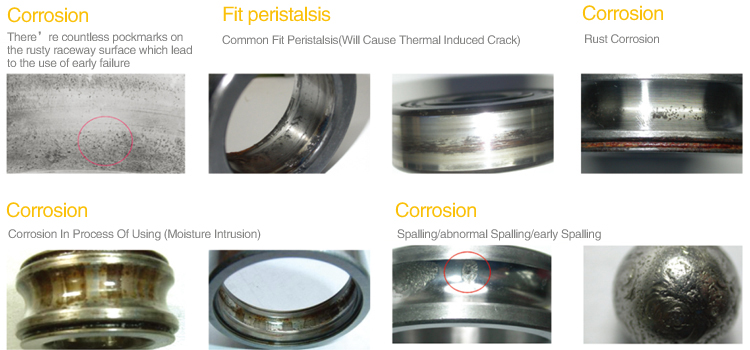

Because the rolling bearing structure and the use of different, leading to its failure reason of diversification. Mainly include: poor assembly, poor lubrication, overload, shock, vibration, abrasive or harmful liquid invasion, the temperature too high or too low, material defects, low manufacturing precision and miscellaneous bulk current role.

the working conditions of complexity, two or more failure mechanism may play a role at the same time, in this case performance for single failure form, in other cases showed multiple failure modes of combination.

|